The Art and Engineering of Glass Sliding Doors: A Deep Dive into High-End Manufacturing

Introduction

The Evolution of Glass Sliding Doors

Early Designs and Functional Beginnings

Modern Applications

-

Residential spaces (patios, balconies, room dividers) -

Commercial buildings (offices, hotels, malls) -

Luxury villas and high-rise apartments -

Industrial and institutional facilities

Why High-End Engineering Matters

Key Advantages of High-End Engineering:

-

Superior Structural Integrity -

High-end sliding doors are engineered to withstand heavy loads, frequent use, and environmental stressors (wind, temperature changes). -

Advanced track and roller systems ensure smooth operation without jamming or wear.

-

-

Enhanced Security Features -

Multi-point locking mechanisms, tempered or laminated glass, and reinforced frames prevent break-ins. -

Anti-lift and anti-slide technologies add an extra layer of protection.

-

-

Thermal and Acoustic Insulation -

Double or triple glazing with low-emissivity (Low-E) coatings improves energy efficiency. -

Specialized gaskets and spacers reduce noise pollution, making them ideal for urban environments.

-

-

Aesthetic Precision -

Minimalist profiles, frameless designs, and custom finishes (brushed nickel, matte black, gold) cater to high-end interiors. -

Seamless integration with smart home systems (automatic opening, sensors).

-

Materials and Construction: The Foundation of Quality

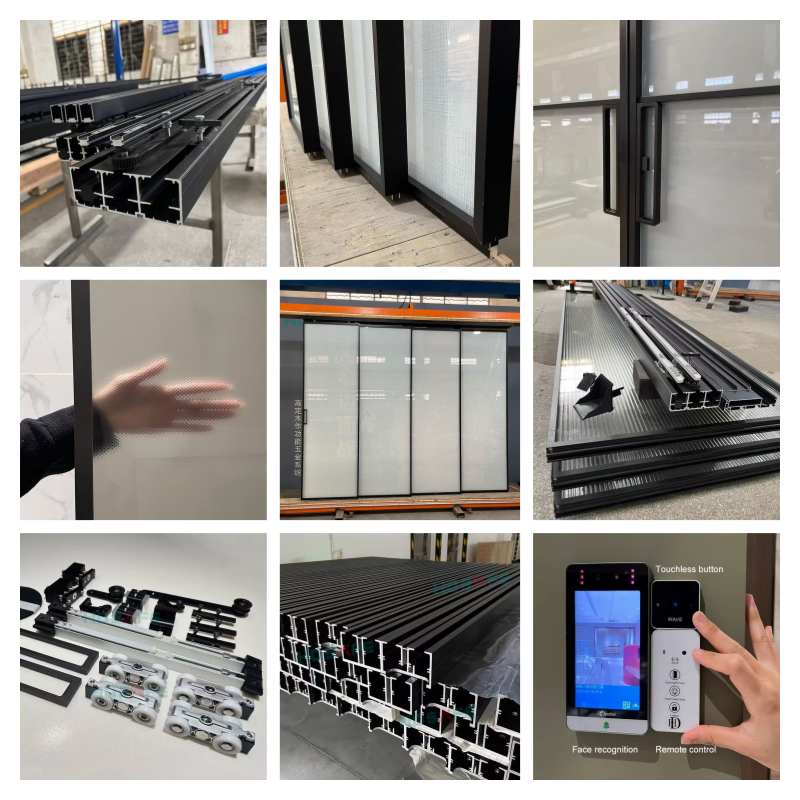

1. Glass Types

-

Tempered Glass: Heat-treated for strength, shatters into small, safe pieces upon impact. -

Laminated Glass: Features a plastic interlayer that holds shards together, enhancing security. -

Low-E Coated Glass: Reflects heat while allowing light, improving energy efficiency. -

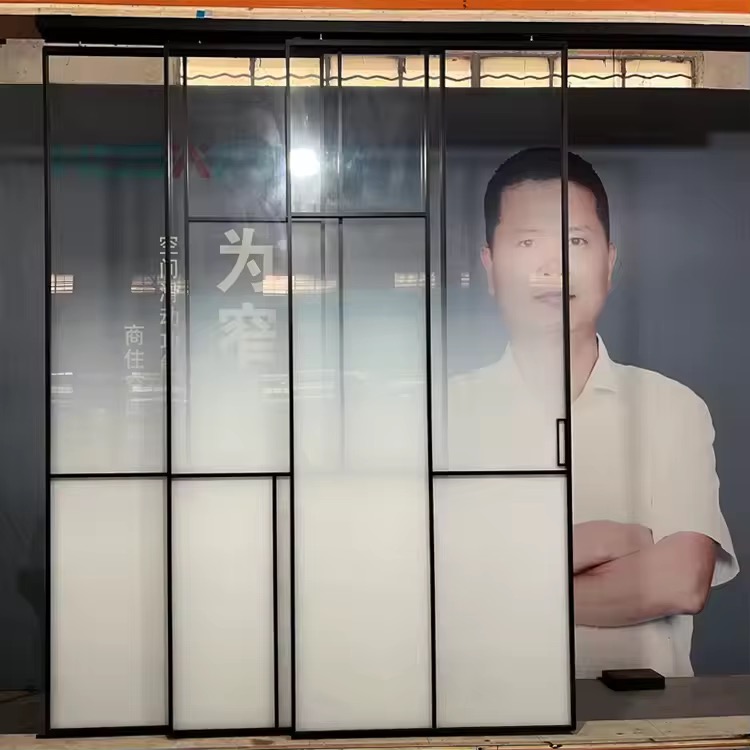

Frosted/Obscured Glass: Provides privacy without sacrificing light.

2. Frame Materials

-

Aluminum: Lightweight, corrosion-resistant, and highly durable—ideal for high-rise buildings. -

Stainless Steel: Offers unmatched strength and a sleek, modern look. -

Wood (Premium Hardwoods): For a classic aesthetic, often paired with aluminum cladding for weather resistance.

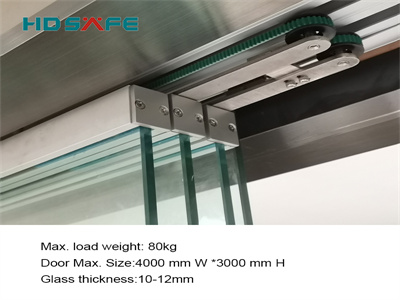

3. Hardware and Mechanisms

-

High-Precision Rollers: Ensure smooth gliding with minimal friction. -

Reinforced Tracks: Prevent warping and misalignment over time. -

Smart Locking Systems: Offer keyless entry and remote control options.

Our Advantage as a Source Factory

1. Customization at Its Core

-

Tailored designs to fit unique architectural requirements. -

Bespoke sizes, colors, and finishes for high-end projects.

2. Strict Quality Control

-

Every sliding door undergoes rigorous testing for durability, safety, and performance. -

ISO-certified production processes ensure consistency.

3. Cost Efficiency Without Compromise

-

Eliminating intermediaries allows us to offer competitive pricing without sacrificing quality. -

Bulk order discounts for large-scale commercial projects.

4. Sustainable Manufacturing

-

Use of recyclable materials and eco-friendly production techniques. -

Energy-efficient manufacturing processes to reduce carbon footprint.

Applications in High-End Projects

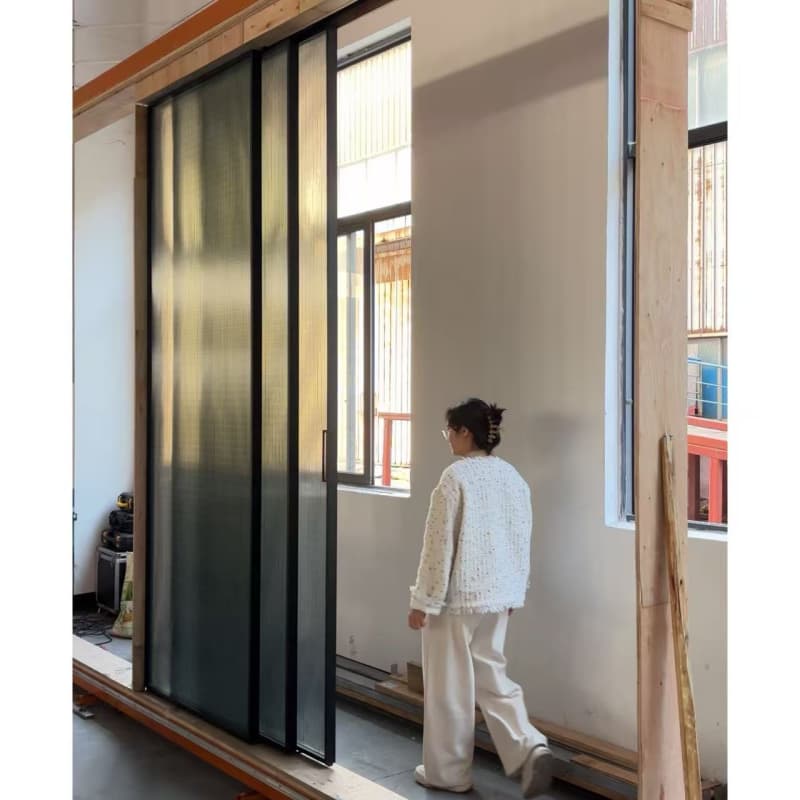

1. Luxury Residences

-

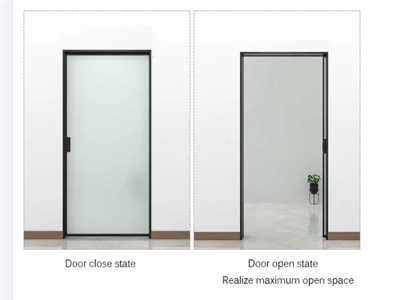

Floor-to-ceiling glass walls that blur the line between indoor and outdoor spaces. -

Frameless designs for a seamless, ultra-modern look.

2. Corporate Offices & Hotels

-

Glass partitions that enhance natural light while maintaining privacy. -

Automatic sliding doors for high-traffic areas.

3. Retail & Commercial Spaces

-

Showcase windows that attract customers while providing security. -

Glass storefronts with reinforced structures.

Future Trends in Glass Sliding Door Technology

-

Self-Cleaning Glass: Nano-coatings that repel dirt and water. -

Smart Glass: Electrochromic glass that adjusts tint based on sunlight. -

AI-Integrated Systems: Voice-controlled and motion-sensing sliding doors.

Home

Home Oct 10,2025

Oct 10,2025

The Ultimate Guide to High-End Glass Sliding Doors: Precision Engineering, Unmatched Quality, and Expert Craftsmanship from a 30-Year Source Factory

The Ultimate Guide to High-End Glass Sliding Doors: Precision Engineering, Unmatched Quality, and Expert Craftsmanship from a 30-Year Source Factory

Jul 23,2025

Jul 23,2025