Choosing the Right Material for Your Glass Sliding Doors

Selecting the right material for your glass sliding doors is one of the most important decisions you’ll make — it affects durability, energy efficiency, maintenance, security, and overall aesthetics. With options ranging from aluminum and wood to vinyl, fiberglass, composite, and steel, each material brings distinct advantages and trade-offs. Below is a detailed guide to help you match the best material to your climate, budget, design goals, and performance needs.

1. Why Material Choice Matters

The frame material determines:

-

Strength & Longevity – Resistance to warping, corrosion, rot, and impact.

-

Thermal Performance – Insulation properties that influence heating and cooling costs.

-

Maintenance – Effort required to keep the door looking new.

-

Security – Ability to withstand forced entry and harsh weather.

-

Style Compatibility – How well it matches your home’s architecture.

Since sliding doors often cover large glass areas, the frame material also impacts the overall structural stability and visual appeal.

2. Overview of Main Materials

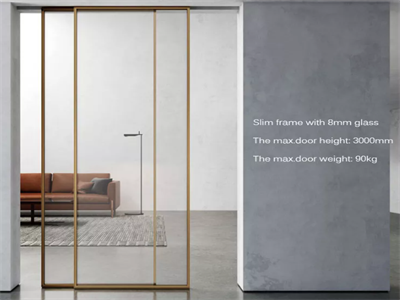

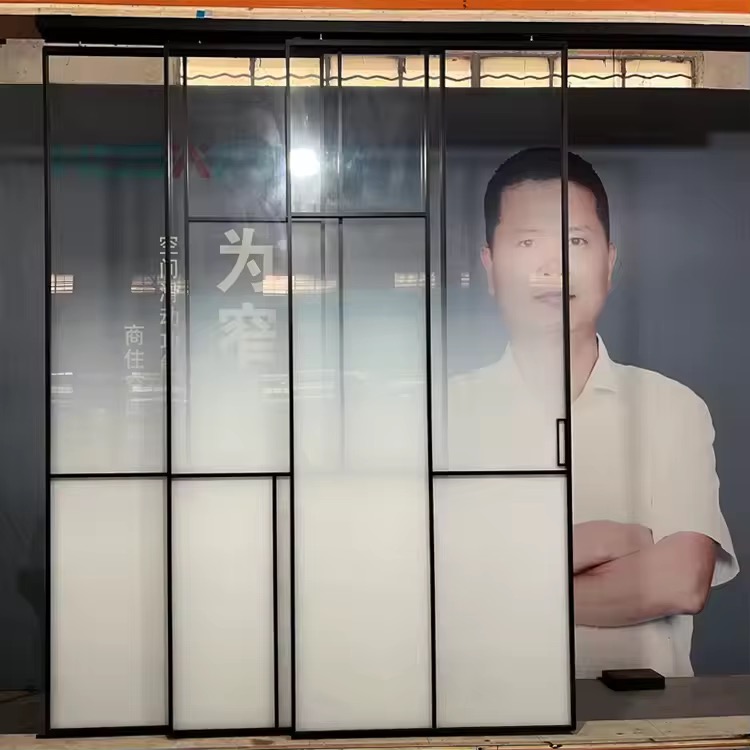

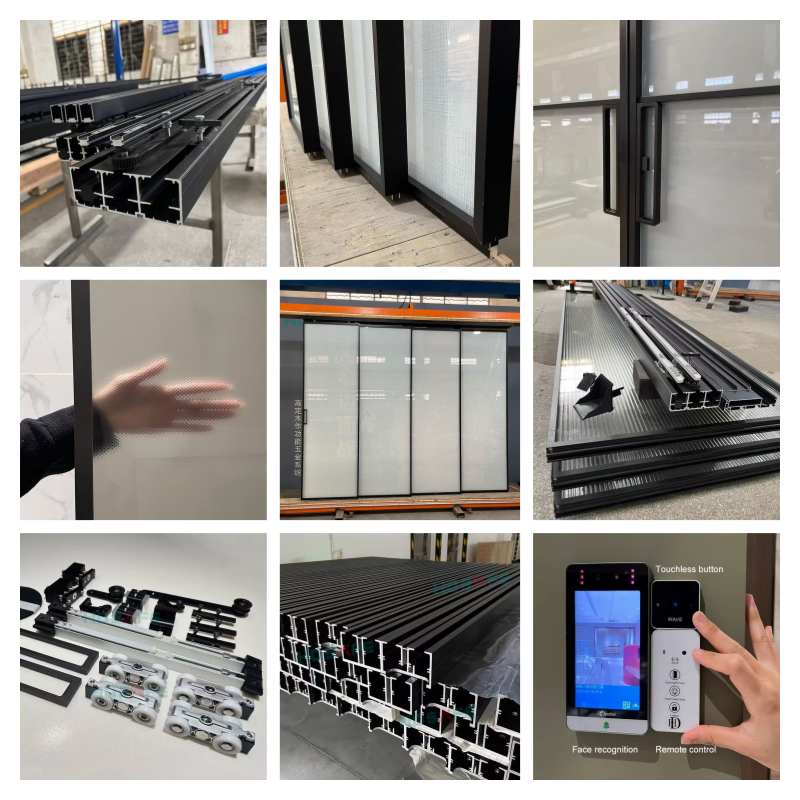

2.1 Aluminum

Profile: Slim, strong, lightweight metal.

Key Features:

-

Naturally corrosion-resistant; powder-coated or anodized finishes prevent fading/chipping.

-

Can be thermally broken (insulating plastic strip inside the frame) to improve energy efficiency.

-

Supports very large glass panels due to high strength-to-weight ratio.

Pros:

✅ Extremely durable — lasts 30–45+ years with minimal degradation.

✅ Low maintenance — occasional cleaning is enough.

✅ Resists moisture, termites, and salt air (ideal for coastal areas).

✅ Slim sightlines maximize glass area and views.

Cons:

❌ Conducts heat/cold unless thermally broken (lower efficiency in extreme climates).

❌ More expensive than vinyl.

❌ May feel less warm or traditional compared to wood.

Best For: Modern homes, large openings, coastal regions, and contemporary architecture.

2.2 Wood

Profile: Natural, warm aesthetic with traditional appeal.

Key Features:

-

Excellent insulator when solid or properly sealed.

-

Can be stained or painted to match any décor.

-

Often combined with aluminum or vinyl cladding on exterior faces for weather resistance.

Pros:

✅ Timeless beauty and charm.

✅ Superior thermal performance (solid wood outperforms non-thermally broken aluminum).

✅ Can last generations with proper care.

Cons:

❌ Prone to warping, cracking, and rotting if exposed to moisture without cladding.

❌ Requires regular sealing, painting, or staining.

❌ Higher long-term maintenance effort.

Best For: Traditional, craftsman, and historic-style homes in temperate, low-humidity climates.

2.3 Vinyl (PVC)

Profile: Affordable, moisture-resistant synthetic material.

Key Features:

-

Multi-chambered hollow cores provide insulation.

-

Fusion-welded corners prevent water infiltration.

-

Color molded throughout — no paint needed.

Pros:

✅ Excellent moisture and corrosion resistance.

✅ Very low maintenance — resists peeling, fading, chipping.

✅ Affordable upfront cost.

Cons:

❌ Can warp or crack in extremely hot climates or under intense sun exposure.

❌ Limited color/finish options compared to aluminum or wood.

❌ Less structurally strong for very large glass panels.

Best For: Budget-friendly homes in moderate climates; standard-sized patio doors.

2.4 Fiberglass

Profile: Composite of glass fibers and resin — exceptionally strong and durable.

Key Features:

-

Can mimic wood grain without the maintenance.

-

Excellent thermal performance due to low conductivity.

-

Resistant to expansion/contraction from temperature swings.

Pros:

✅ Exceptional durability — resists warping, rotting, corrosion.

✅ Performs well in extreme temperatures (hot or cold).

✅ Low maintenance — can be painted or factory finished.

✅ Strong enough for large glass sizes.

Cons:

❌ Higher initial cost than vinyl and some wood options.

❌ Fewer style variations compared to aluminum.

❌ Professional installation recommended due to weight.

Best For: Harsh climates (very hot, cold, or coastal), luxury homes, and anyone prioritizing longevity with minimal upkeep.

2.5 Composite (Wood-Plastic or Aluminum-Wood)

Profile: Blends materials to optimize durability and insulation.

Key Features:

-

Resists rot, decay, and insects like vinyl or aluminum.

-

Can offer wood-like aesthetics with better moisture resistance.

-

Some designs include thermal breaks for improved efficiency.

Pros:

✅ Strong and stable — less prone to warping than pure wood.

✅ Good insulation properties.

✅ Low maintenance with wood-like appearance.

Cons:

❌ Costlier than vinyl; comparable to fiberglass.

❌ Performance varies by brand and exact composite mix.

❌ May not match the strength of high-grade aluminum or fiberglass for huge openings.

Best For: Homeowners wanting wood aesthetics without the maintenance, especially in mixed-humidity climates.

2.6 Steel

Profile: Ultra-strong, thin metal often used in industrial or luxury designs.

Key Features:

-

High load-bearing capacity for oversized glass panels.

-

Sleek, minimal profiles.

-

Often paired with glass for modern, high-end look.

Pros:

✅ Maximum strength and slim sightlines.

✅ Long-lasting with proper finishing (powder coat or hot-dip galvanizing).

✅ Distinctive industrial or contemporary aesthetic.

Cons:

❌ Heavy — requires reinforced framing and professional installation.

❌ Susceptible to rust if coating is damaged (needs prompt repair).

❌ Higher cost and maintenance than aluminum.

Best For: Industrial lofts, luxury modern homes, and commercial spaces needing maximum strength and minimalist design.

3. How to Choose the Right Material

Step 1 – Assess Your Climate

-

Hot/Sunny: Fiberglass or thermally broken aluminum to resist expansion and UV degradation.

-

Cold/Wet: Fiberglass or wood-clad aluminum for insulation and moisture resistance.

-

Coastal/Salt Air: Aluminum or fiberglass (corrosion-resistant).

-

Humid: Vinyl, fiberglass, or composite (rot/mold resistant).

Step 2 – Determine Performance Priorities

-

Energy Efficiency: Fiberglass > wood-clad aluminum > thermally broken aluminum > composite > vinyl > non-thermally broken aluminum.

-

Security: Steel > aluminum > fiberglass > wood-clad > composite > vinyl.

-

Low Maintenance: Vinyl, fiberglass, aluminum (powder-coated).

Step 3 – Match Style & Architecture

-

Modern/Contemporary: Aluminum, steel, or composite with slim frames.

-

Traditional/Craftsman: Wood or wood-clad aluminum.

-

Industrial/Loft: Steel or blackened aluminum.

-

Coastal: Aluminum or fiberglass in white/neutral finishes.

Step 4 – Set Your Budget

Balance upfront cost with long-term maintenance and replacement expenses. Fiberglass and aluminum are higher initial investments but offer lower lifetime costs due to durability.

4. Pro Tips for Material Selection

-

Thermal Breaks: Always opt for thermally broken aluminum if energy efficiency is a priority in colder or hotter climates.

-

Cladding: Choose wood-clad aluminum or vinyl-clad wood for the warmth of wood with exterior durability.

-

Finish Quality: Powder-coated aluminum and factory-painted fiberglass resist fading better than standard paints.

-

Certifications: Look for ENERGY STAR® ratings and NFRC (National Fenestration Rating Council) labels for verified performance.

-

Professional Advice: Consult manufacturers or architects to ensure material choice aligns with structural needs and local building codes.

Conclusion

Choosing the right material for your glass sliding doors is about balancing climate demands, performance needs, design goals, and budget.

-

For maximum durability and energy efficiency: Fiberglass is the top performer.

-

For modern aesthetics and strength: Thermally broken aluminum is a close second.

-

For traditional warmth: Wood (with cladding) offers timeless beauty.

-

For tight budgets: Vinyl provides good moisture resistance at a lower cost.

-

For luxury and industrial style: Steel gives unmatched strength and sleekness.

By carefully evaluating these factors, you can select a material that not only looks stunning but also delivers lasting performance and value for your home.

Home

Home Jan 05,2026

Jan 05,2026

Understanding Different Types of Glass Railing Systems and Their Advantages Across Applications

Understanding Different Types of Glass Railing Systems and Their Advantages Across Applications

Dec 31,2025

Dec 31,2025